Introduction

TMT bars or Thermo-Mechanically Treated bars are high-strength reinforcement bars having a tough outer core and a soft inner core. Thermo-Mechanically Treated bars or TMT bars are widely used for different construction projects. Made from high strength steel, TMT bars possess several qualities that make them the most preferred material for various construction projects. With a unique metallurgical process that combines work hardening along with heat treatment to create robust and high-strength bars from low-carbon steel, TMT bars have a great demand.

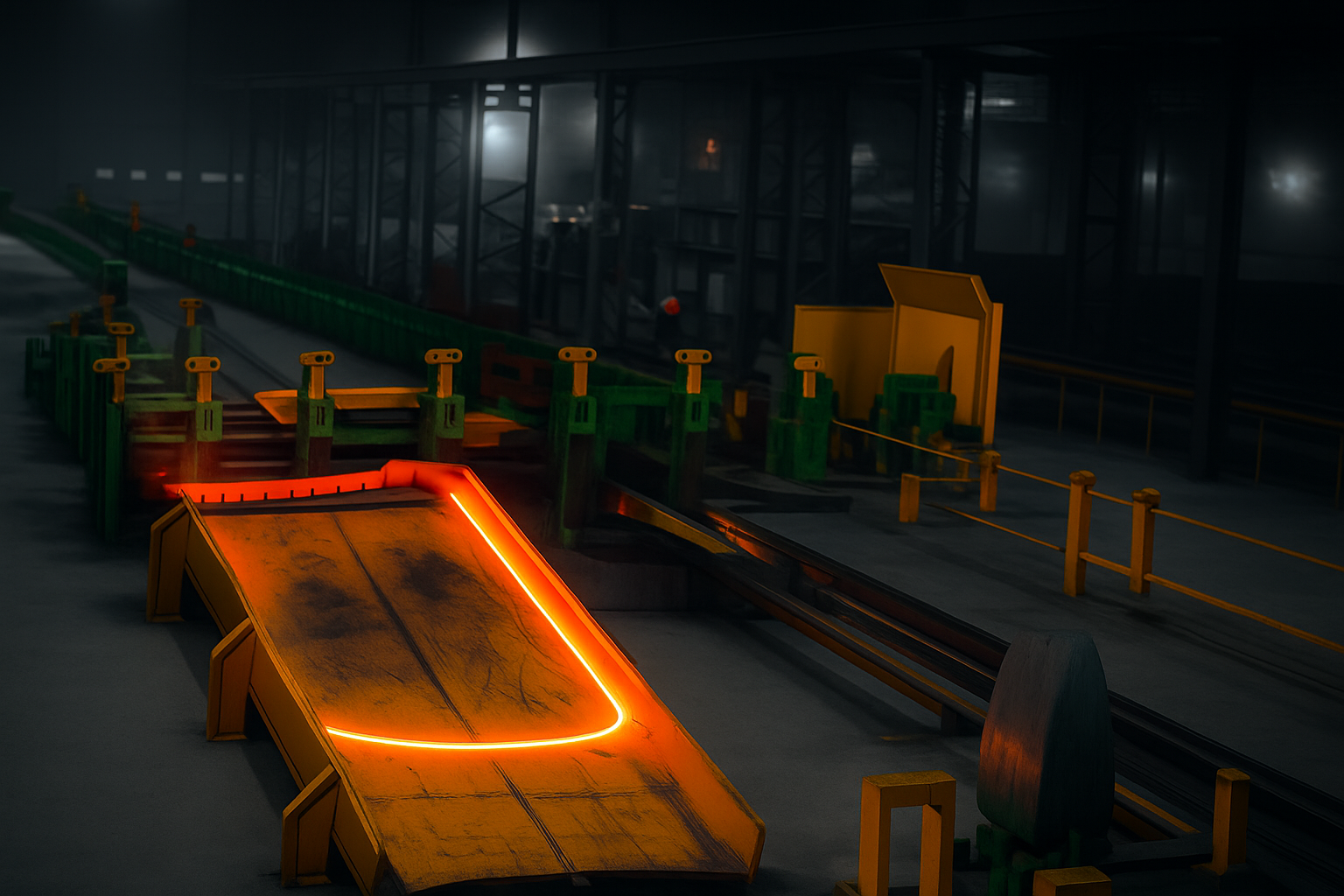

The manufacturer of TMT Bars lets the raw materials pass through various processes that help build its robustness and flexibility. The entire manufacturing process involves rolling, heat treatment at different stages, quenching, self-tempering, and leaving the final product for atmospheric cooling.

From the above, we can say that the entire manufacturing process revolves around four major components:

Thermo Mechanical Treatment"TMT bars stand for Thermo Mechanical Treated Bars. The bars produced in the factory pass through different handling methods. These include:

Process

Conversion of Billets to steel

Once the billets attain desired rolling temp it is ejected from the furnace. Then with the help of a rolling conveyor, these billets are made to pass through 1 stand i.e.Roughing stand. Temperature prior to rolling is also monitored by St optical pyrometer. This begins the process of gradual size reduction of billets. Following roughing mill, the size is further reduced in intermediate & finishing Mill. This gradual reduction is an important factor to ensure the finer grain structure of the bar. The rolling continues till the required size is achieved with the help of Roller Bearing Fitted roll, it prevents any unnecessary deformation of the bar. The loop scanners in the flow of the bar ensure a perfectly tensionless rolling process & result in the perfectly round shape of the bar. The surface characteristics of the steel are finalized in this section only.

Quenching

Once the hot rolled bars releases from finished mill it enters to the water spray system that is known as ‘Thermex System’. The best quality tmt bars manufacturing process uses Thermex Technology that cool down the outer core rapidly and ensure the ductility of TMT Rebars. Rapid cooling hardens the outer core of the TMT Rebars to a depth optimized for each section, forming a martensitic rim while the core remains hot & Austenitic.

Self Tempering

It is the stage when the outer core of the TMT bars gets temperament on its own. As the TMT Bars team manufacturer releases the bars from the quenching box, the inner core is at a more heated stage than the surface. The heat thus passes from the inner core to the surface following the heat passage principles. Passage of heat from the inner core to the outer causes convectional tempering of the surface. According to experts, temperament accounts for a correct reconditioning of the martensitic layer. The outer layer of the TMT bars thus arrives as a combination of martensitic and bainitic formation. The inner core, however, remains hot and austenitic. It is the ideal form of TMT bars in India.

Atmospheric Cooling

Once the self tempering is over the bars get ready for atmospheric cooling. This is done on cooling bed on normal temperature. In this step the austenitic core turns as ferrite-pearlite structure. Thus the final structure consists of strong outer layer with ductile core. This process increases the tensile strength that makes it highly ductile and weldable.

FE 500

Provident nihil minus qui consequatur non omnis maiores. Eos accusantium minus dolores iure perferendis tempore et consequatur.

| Property | IS:1786 | GM TMX |

|---|---|---|

| 0.2% Proof Stress/Yield Stress (min N/mm2) | 500 | 520 |

| Tensile Stress (min N/mm2) | 545 | 580 |

| UTS/YS Ratio | - | 1.12 |

| Elongation % Min | 12 | 18 |

| Total Elongation % Min | - | 5 |

| Property | IS:1786 | GM TMX |

|---|---|---|

| C% Max. | 0.300 | 0.250 |

| S% Max. | 0.055 | 0.050 |

| P% Max. | 0.055 | 0.050 |

| S+P (%) Max. | 0.105 | 0.100 |

| CE% | 0.420 | 0.420 |

FE 500 D

Ut autem aut autem non a. Sint sint sit facilis nam iusto sint. Libero corrupti neque eum hic non ut nesciunt dolorem.

| Property | IS:1786 | GM TMX |

|---|---|---|

| 0.2% Proof Stress/Yield Stress (min N/mm2) | 500 | 530 |

| Tensile Stress (min N/mm2) | 265 | 600 |

| UTS/YS Ratio | 1.10 | 1.12 |

| Elongation % Min | 16 | 18 |

| Total Elongation % Min | 5 | 7 |

| Property | IS:1786 | GM TMX |

|---|---|---|

| C% Max. | 0.250 | 0.250 |

| S% Max. | 0.040 | 0.040 |

| P% Max. | 0.040 | 0.040 |

| S+P (%) Max. | 0.075 | 0.075 |

| CE% | 0.420 | 0.420 |

FE 550

Ut excepturi voluptatem nisi sed. Quidem fuga consequatur. Minus ea aut. Vel qui id voluptas adipisci eos earum corrupti.

| Property | IS:1786 | GM TMX |

|---|---|---|

| 0.2% Proof Stress/Yield Stress (min N/mm2) | 550 | 570 |

| Tensile Stress (min N/mm2) | 585 | 650 |

| UTS/YS Ratio | - | - |

| Elongation % Min | 10 | 15 |

| Total Elongation % Min | - | - |

| Property | IS:1786 | GM TMX |

|---|---|---|

| C% Max. | 0.300 | 0.250 |

| S% Max. | 0.055 | 0.040 |

| P% Max. | 0.050 | 0.040 |

| S+P (%) Max. | 0.105 | 0.080 |

| CE% | - | - |

FE 550 D

Non et temporibus minus omnis sed dolor esse consequatur. Cupiditate sed error ea fuga sit provident adipisci neque.

| Property | IS:1786 | GM TMX |

|---|---|---|

| 0.2% Proof Stress/Yield Stress (min N/mm2) | 550 | 570 |

| Tensile Stress (min N/mm2) | 600 | 630 |

| UTS/YS Ratio | 1.08 | 1.1 |

| Elongation % Min | 14.5 | 16 |

| Total Elongation % Min | 5 | 6 |

| Property | IS:1786 | GM TMX |

|---|---|---|

| C% Max. | 0.250 | 0.240 |

| S% Max. | 0.040 | 0.040 |

| P% Max. | 0.040 | 0.040 |

| S+P (%) Max. | 0.075 | 0.075 |

| CE% | 0.420 | 0.420 |